Technology News: Innovation by Jakob Müller AG

Gather information about new Müller machines and technology updates, as well as the latest software and software releases.

EBRT AND EKAST

CONSTANT AND CONTROLLED THREAD TENSION WITH EBRT AND EKAST

EBRT and EKAST provide constant, controlled warp thread tension and with these solutions for weaving from the creel and the warp beam, the productivity of Müller machines can be increased even further.

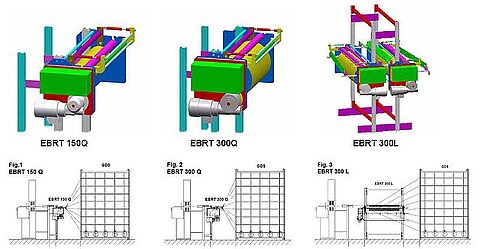

During the weaving of medium-weight to heavy belts from the creel, the positive driven EBRT brake drum controls the warp thread transport. The drum is available in variations with diameters of 150mm (EBRT 150Q), 300mm (EBRT 300Q) and twice 300mm (EBRT 300L). The EBRT 300L also allows the new, optional addition of integrated warp thread feed monitoring and improved selvedge thread tension regulation using a brake lever.

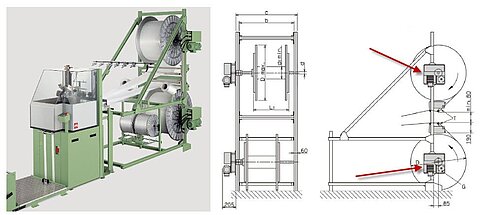

Jakob Müller AG has also developed the EKAST electronic warp take-off control for weaving from the warp beam. This option is available in the EKAST 50.1 variant for warp tension up to 500N.

In combination, the EBRT and EKAST offer a range of advantages:

- Constant and controlled warp thread tension during the entire weaving process

- Higher productivity

- Improved product quality and less waste

- Reduced downtimes

Would you like to use EBRT or EKAST on your already installed or new machines? Does a standard solution fit or do you need individual adaptations? Our spare parts service will be happy to advise you.

Jakob Müller AG Frick

Spare Part Service

parts.jmf@mueller-frick.com