Technology News: Innovation by Jakob Müller AG

Gather information about new Müller machines and technology updates, as well as the latest software and software releases.

NH2 53 - MORE POWERFUL TAPE TAKE-OFF

MORE POWERFUL TAPE TAKE-OFF FOR THE NH2 53 NARROW FABRIC LOOM

Thanks to a new tape take-off with a force of 2,500 N, the electronically controlled NH2 53 loom for light- to medium-weight tapes now offers even greater operational flexibility.

The electronically controlled NH2 53 narrow fabric loom is designed for the production of light- to medium-weight tapes. The take-offs installed to date possessed appropriately defined forces, consisting of 550 N for the NH2 53 2/130, 1,000 N for the NH2M 53 for cord and ropes and 1,500 N for the NHJM2 53 jacquard loom.

However in some market segments, tapes with higher surface masses are needed and these require take-offs with greater forces. Therefore, Jakob Müller has developed a new module that increases take-off force to a nominal level of 2,500 N in a range of 8 to 60 picks/cm (NH2M 53 with 5 to 60 picks/cm). As of now, this module is being used in the following machine types:

- NH2 53 2/130, NHJM2 53 (both with 75 mm-stroke level)

- NH2M 53 (with 44 mm-stroke level)

The new pre-installed module consists of a 3-step spur gearing with return stop and a 5 Nm motor. The gearing employed offers 81% efficiency, which guarantees a high degree of motor torque utilisation. Moreover, during the design of the gearing the loads on the various machine components, and in particular the deflection rollers, were the object of detailed analysis. The resultant findings then helped to ensure that the strengthened gearing offers excellent fatigue endurance. Subsequently, the new tape take-off was subjected to thorough testing at various customer companies.

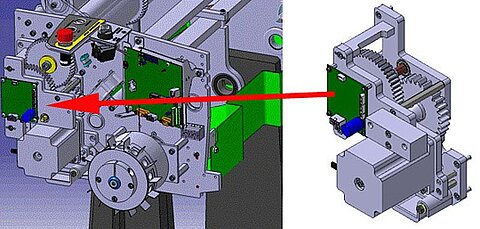

The illustration shows the layout of the strengthened tape take-off on an NH2 53 2/130. It should be noted that on this machine, the right-hand casing must also be exchanged. A double tape take-off is always foreseen for the NH2 53 2/130 and NHJM2 53 looms.

The augmented gearing is installed in the aforementioned machine types ex-works and replaces the versions employed to date. An upgrade of existing machines is also possible and the customer can implement the modifications autonomously (modification instruction A8564). Nonetheless, we recommend that the new module be installed by an experienced Jakob Müller engineer, as the anchorage of the new tape take-off requires a number of alterations to the machine’s side panel.

The module can be ordered as a conversion kit from Jakob Müller AG’s Spare Part Service using the machine number. Should the customer so require, the assistance of a service engineer can also be made available along with the conversion kit.

Jakob Müller AG Frick

Spare Part Service

parts.jmf@mueller-frick.com